What makes Puretecs special

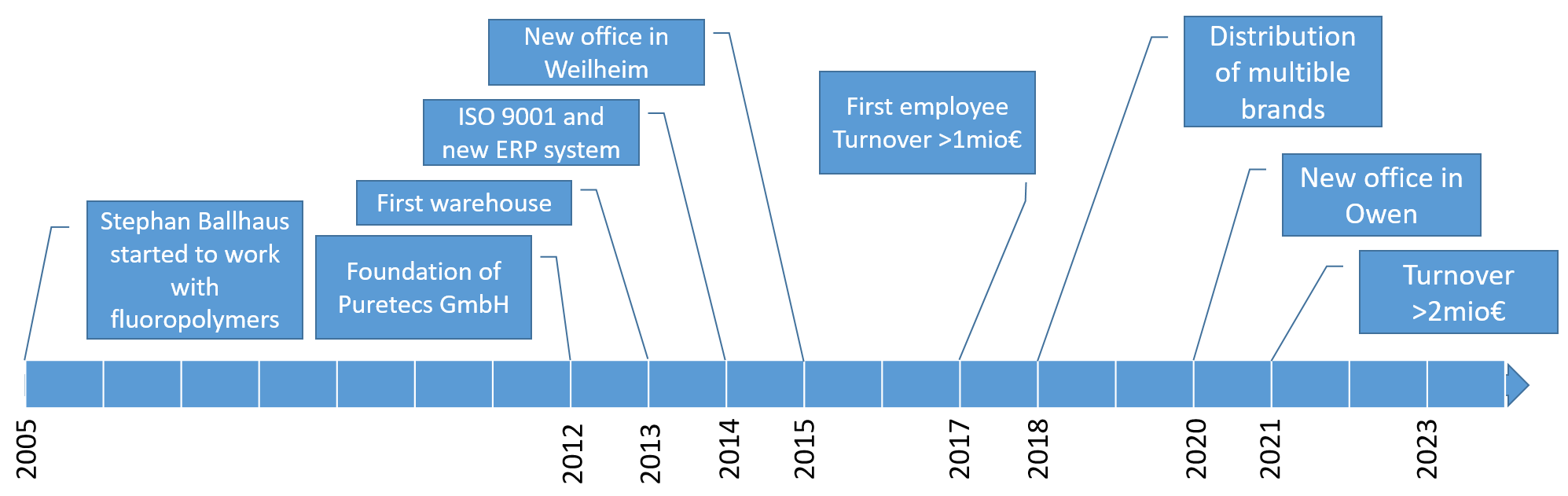

Stephan Ballhaus has been working on protective coatings for electronics since 2005: It all started with the introduction of the new process of applying ultra-thin fluoropolymers to the entire surface of PCBAs using an immersion bath without affecting to electrical contacts.

A little later, in 2012, Puretecs GmbH was founded in order to realize the preparation of the PCBAs in terms of process technology in addition to the sale of the coating materials and the system technology. The range has been expanded to include cleaning solutions - both for electronic assemblies and for precision parts and optics.

In 2015, Stephan Ballhaus and Johannes Ballhaus entered Puretecs GmbH full-time and made the protective coating the main product. Johannes Ballhaus previously worked full-time as a product developer in an international company for 11 years.

The portfolio has been continuously expanded to include the full range of protective coatings. In addition to the cleaning solutions for water-free cleaning, environmentally friendly and safe cooling liquids are now also supplied for the direct and indirect cooling of computer boards, motors and high-performance batteries.

Puretecs now offers many years of expertise in protective coatings, cleaning, cooling, sample production, testing, plant construction, process development and a large distribution warehouse for all common materials.

Puretecs develops optimized solutions for the protective coating of PCBAs.

We have a wide portfolio of protective coating materials and technologies. From ultra-thin coatings to varnishes and potting materials.

With our innovative coating systems in the field of fluoropolymer coating, we offer you convenient and cost-effective complete solutions.

Only the interaction of perfect materials, systems and logistics can lead to success; That is why we offer the latest materials of the world market in Europe.

With our distribution warehouse, Puretecs offers overseas companies a good sales platform in Central Europe.